In the rapidly evolving furniture and interior sector, managing products with countless variations and configurations has become one of the industry’s biggest challenges. Traditional ERP systems often struggle to handle such complexity effectively. This is where TRIMIT comes in – a powerful yet user-friendly solution that streamlines the entire product management process, from design to production.

Built on Microsoft Dynamics 365, it provides all the tools necessary to make production processes smoother and more efficient from start to finish.

Imagine being able to create, manage, and maintain an unlimited number of SKUs easily and effectively. TRIMIT’s configuration engine is specifically designed for the furniture and interior industry, offering tools that help track trends, eliminate order errors, and improve customer service.

No detail is left unchecked — from product creation and warehouse management to sales order fulfillment — ensuring that every step of the value chain is connected, transparent, and controlled.

What Makes TRIMIT Furniture & Interior Different?

TRIMIT offers specialized solutions tailored for different industries — for example, it can be used in the fashion sector and other fields where products are similar in type but come with countless variations, and where fabrics or mechanisms change seasonally.

The only function not typically used in the furniture industry is the Matrix feature for sales and purchase orders, where two-dimensional products are entered into a two-dimensional grid. However, lookup tables, which are a variation of the Matrix concept, are widely applied in the furniture sector.

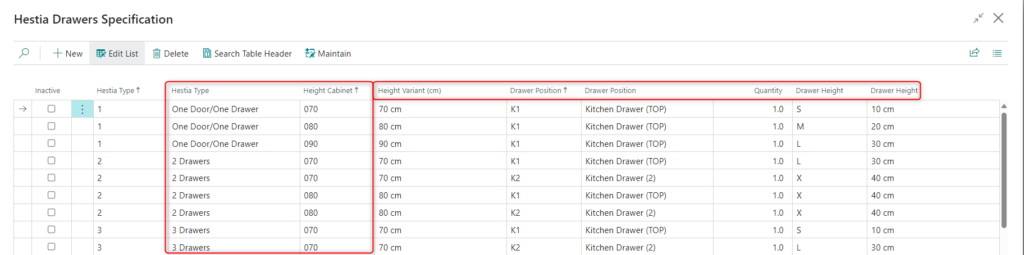

Lookup tables form part of the formula logic created for the industry and serve as a very convenient tool. Simply put, they work like built-in Excel functions such as INDEX and MATCH within TRIMIT.

When a customer makes a selection (for instance, choosing a product with a specific width and length), the system can determine that the price should fall into a specific cell. Or, if the direction of fabric cutting changes because the material must be cut along a certain grain, the corresponding material consumption is automatically adjusted.

Customer Choices Processed Automatically

The furniture and fashion industries share many similarities, especially when fabrics are involved.

For instance, curtain manufacturers often use price lists based on fabric class and width/length ranges. Depending on the fabric’s weight, the curtain mechanism must also change, as heavier fabrics require stronger systems.

Another clear example: if a black stripe is chosen for blinds, all related components (slats, cords, accessories) must also be black. The MASTER BOM (Bill of Materials) must automatically recognize that the components included in the product assembly depend on the chosen color option.

This is why customer-dependent selections must be processed automatically in the furniture and interior sector – without manual intervention.

Collections: A “Headache” Made Simple

Managing collections has traditionally been quite complicated and required a great deal of manual work. In the case of furniture and curtains, we are not dealing with finished end products that can simply be added to a catalog — in most cases, the customer must also choose a fabric or material from specific collections.

Even if the core product remains unchanged, fabric collections are updated every few years. Replacing materials across all products has usually been a time-consuming and error-prone process, requiring BOM changes, new creations, price list updates, and communication with agents.

In TRIMIT, using the MASTER BOM solution makes this process much simpler. You simply create a copy of the previous MASTER card, replace the fabric selections, adjust the prices, and you’re ready to sell again.

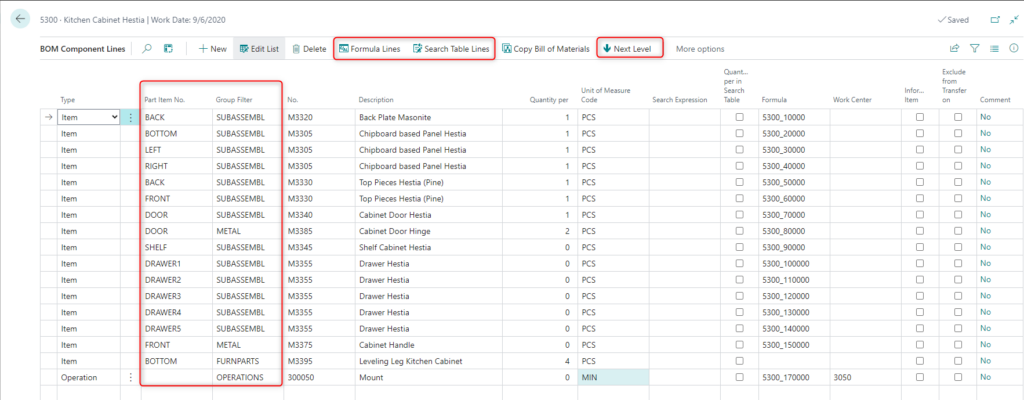

Within the MASTER BOM, components can be grouped in different ways, and groups can be reused later. You can quickly switch from a finished product BOM to a subassembly BOM, while also embedding formulas and lookup tables directly into BOMs or formulas.

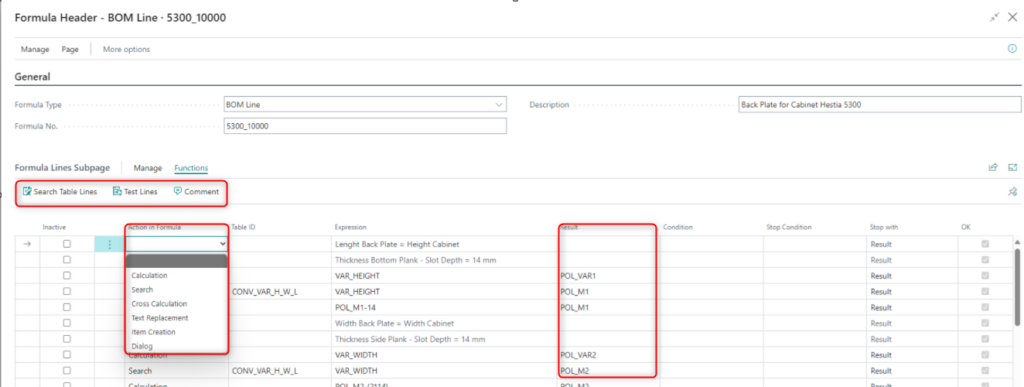

Continuing with examples, we can also see what types of calculations can be done with a formula. It is possible to make a simple calculation where different data can be added, subtracted, multiplied, and divided. The results can also be replaced with something else: for example, if the choice is white, then the cord is also white. Or the formula can look up data according to the customer’s selections from a lookup table – for instance, if the chosen kitchen furniture height is X, then the material cost is Y.

In this example, we can see how a BOM formula line places the formula results into four different variant fields on the production order line (POL), as well as into the quantity field. Thus, depending on the customer’s selection, it is now clear what height and width of drawer must be produced.

Formulas can be used throughout the solution: in sales orders, price lists, BOMs, etc. This helps automate everything that requires calculations.

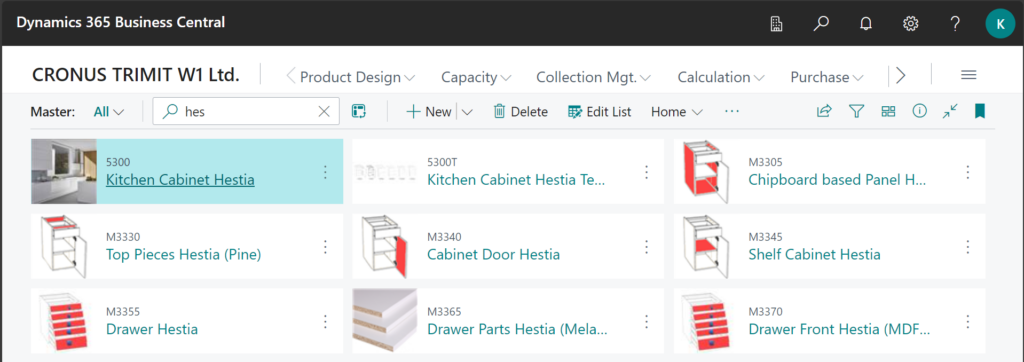

In the third example, we can see how a finished product and its subcomponents are represented as MASTERS. Since the customer can choose between different heights and widths, and also whether drawers are included, not included, or how many should be included, these are not final products or subcomponents but their MASTERS.

Depending on the customer’s selections, a temporary BOM is now created, which is placed on the production order, allowing the exact product requested by the customer to be manufactured. At the same time, manual work in entering product parameters is kept to a minimum: the customer has already provided all the necessary input through their selections, and TRIMIT takes care of the rest automatically.

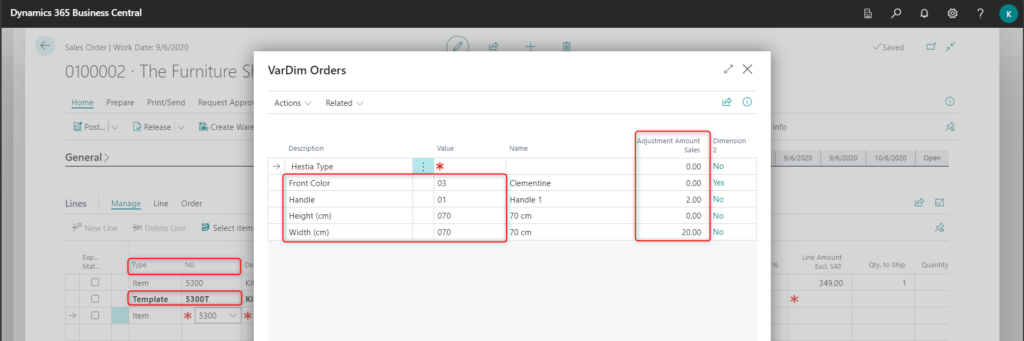

The customer chooses what kind of furniture they need in terms of height, width, and number of drawers (or even without drawers). There is no need to create a separate product for each variant – TRIMIT’s solution helps generate it on the fly, so the correct information reaches production. Below is an example of a lookup table, where the available options depend on the customer’s selection.

How to add these options to sales orders? That too is not complicated and can be done while eliminating much of the manual work.

In cases where repeated selections are needed (for example, with a kitchen furniture section consisting of many components), a template can be used for making the selections. When choosing the corresponding MASTER, a preselection has already been made, and only the content of the ordered cabinet needs to be added: whether with drawers or without, with one drawer and two shelves, etc.

It also becomes immediately clear that, depending on the selection, additional costs may be added to the base price. The product cost price, however, is calculated right after the customer has made their selections, not only at the end of the production process. Both sides benefit: the customer and the manufacturer, because price transparency is achieved instantly right after the product is ordered.

Key Benefits of TRIMIT for the Furniture & Interior Industry

Looking at these examples, it’s clear that TRIMIT removes much of the manual work that typically follows custom orders. Since most products in the furniture and interior sector are customized, automation makes a huge difference.

Here are the eight main benefits TRIMIT delivers:

- Centralized Product Management – manage the entire production and sales process from one place, reducing errors and boosting productivity.

- Ease of Use & Efficiency – a user-friendly system that adapts quickly to customer requirements, ensuring flexible and fast production.

- Automated Choice Handling – automatically adjusts products based on customer selections, including pricing, materials, and BOMs.

- Innovative Lookup Tables – Excel-like functionality for fast, accurate data retrieval and configuration.

- Quick Product Updates – MASTER BOM enables fast copying and modification of components and price lists, helping companies respond to market changes.

- Integrated E-Commerce & Sales – full integration with B2B, B2C, and partner platforms enhances sales and customer satisfaction.

- Real-Time Data & Analytics – with Microsoft Power BI integration, businesses gain clear insights for data-driven decisions.

- Sustainability & Compliance Tracking – easily monitor product environmental impact, generate sustainability reports, and manage certifications.

Conclusion

TRIMIT industrial software takes over the heavy manual work in product management, design, and production processes, making them streamlined and efficient. Whether you are a manufacturer, distributor, or retailer, TRIMIT provides the tools you need to boost business performance and, ultimately, grow revenue.

Contact Us

OIXIO Group